Where Innovation Takes Shape

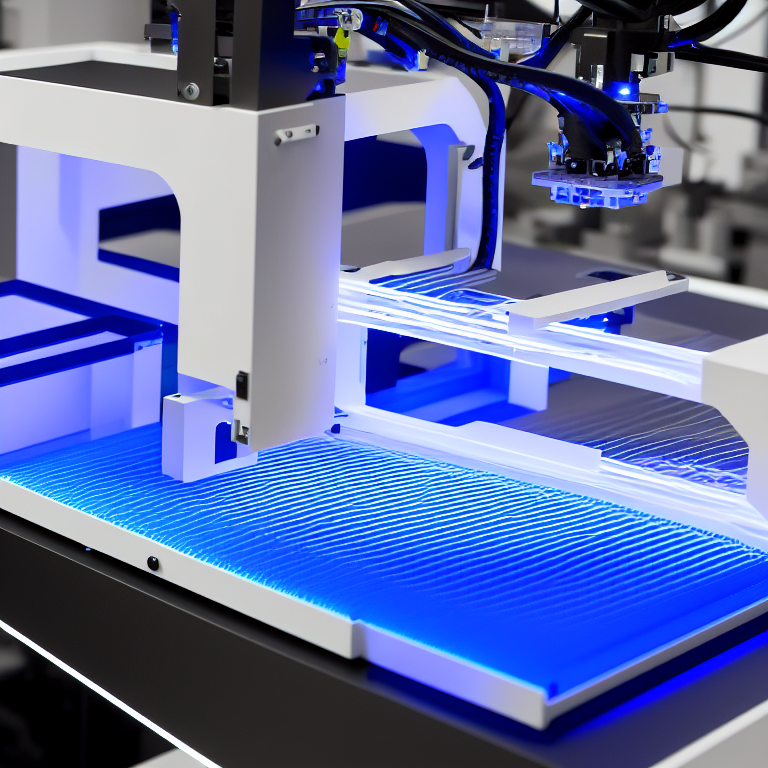

Aerospace & Defense

The ability to rapidly produce lightweight, high-temperature resistant, and geometrically complex ceramic components is critical for next-generation aerospace systems. Slic3D technology enables faster development and potential on-demand manufacturing.

- Heat shields and thermal protection systems

- Turbine engine components (shrouds, blades)

- RF-transparent radomes and sensor housings

- Lightweight structural elements

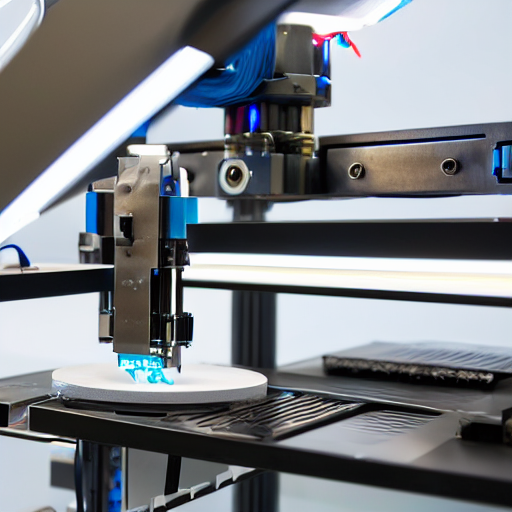

Medical & Dental

Biocompatible ceramics are essential for implants and medical devices. Our rapid sintering process allows for patient-specific designs and potentially enhanced osseointegration through controlled microstructures, reducing lead times significantly.

- Customized bone grafts and cranial implants

- Dental crowns, bridges, and abutments

- Porous scaffolds for tissue engineering

- Surgical guides and instrumentation

Electronics & Energy

Advanced ceramics play a vital role in electronic packaging, high-frequency applications, and energy storage/conversion. Rapid manufacturing enables faster prototyping and production of critical components.

- High-frequency substrates and packages

- Insulators and dielectric components

- Solid-state battery electrolytes and electrodes

- Sensor components for harsh environments

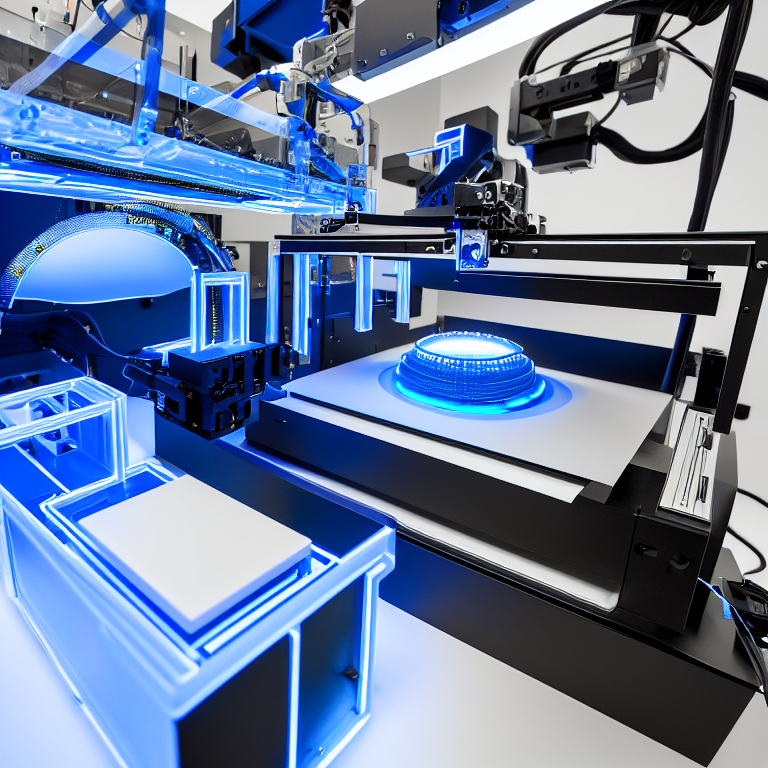

Research & Development

Slic3D technology provides materials scientists and researchers with an unparalleled tool for accelerating discovery. Rapidly test new compositions, optimize process parameters, and create novel structures for experimentation.

- Accelerated materials discovery cycles

- Fast validation of new ceramic formulations

- Fabrication of complex experimental apparatus

- Process parameter optimization studies

Imagine the Possibilities

Have a specific challenge where rapid ceramic manufacturing could make a difference? Let's explore it together.

Contact Our Team